About Conveyor Belt

Introduction About Conveyor Belt on Umar Farooq Belting:

Umar Farooq Belting is a leading provider of high-quality conveyor belts designed to meet the diverse needs of industries worldwide. With a commitment to innovation, durability, and customer satisfaction, our conveyor belts are crafted using state-of-the-art technology and premium materials. Whether you operate in manufacturing, mining, agriculture, or any other industry, Umar Farooq Belting delivers reliable and efficient conveyor belt solutions.

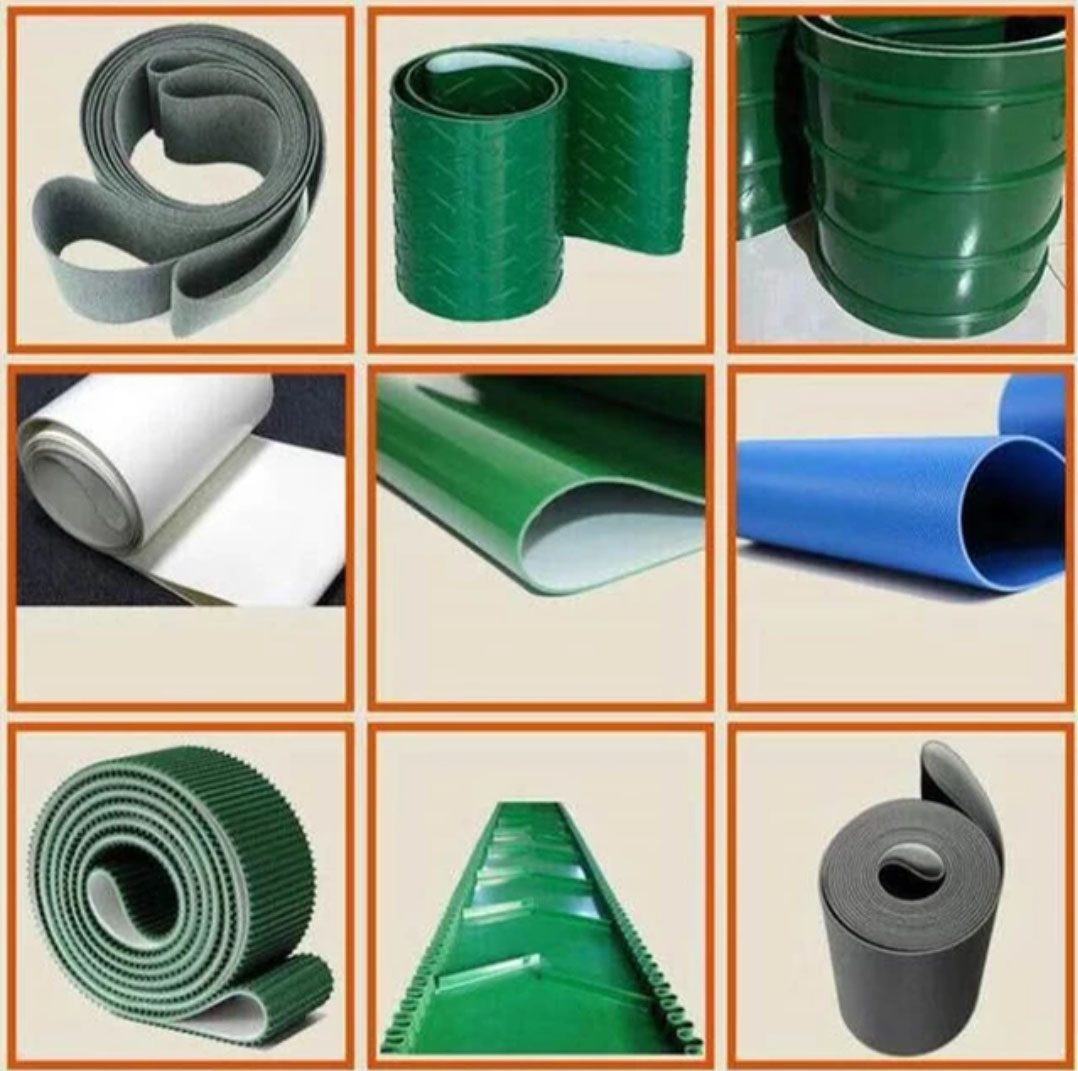

Types of Conveyor Belts:

- Flat Belt Conveyors:

- Ideal for horizontal transportation of goods.

- Suited for light to medium-duty applications.

- Commonly used in manufacturing and packaging industries.

- Modular Belt Conveyors:

- Consist of individual interlocking modules for versatile configurations.

- Suitable for conveying a wide range of products, from small items to heavy loads.

- Commonly found in food processing, automotive, and warehousing applications.

- Cleated Belt Conveyors:

- Feature cleats or vertical ribs to prevent materials from sliding off.

- Ideal for incline or decline applications, ensuring efficient material transport.

- Used in industries like agriculture, mining, and bulk material handling.

- Steel Cord Conveyor Belts:

- Reinforced with steel cords for high tensile strength and durability.

- Suited for heavy-duty applications, such as mining, construction, and steel production.

- Resistant to impact and abrasion, ensuring a longer operational life.

- Heat Resistant Conveyor Belts:

- Designed to withstand high temperatures, making them suitable for industries like foundries, cement, and steel.

- Ideal for conveying hot materials without compromising performance.

Uses of Conveyor Belts:

- Manufacturing and Assembly Lines:

- Facilitate the efficient movement of products during production processes.

- Improve overall workflow and reduce manual handling.

- Mining and Quarrying:

- Essential for transporting bulk materials, such as ores and aggregates.

- Designed to withstand harsh conditions and heavy loads.

- Agriculture:

- Used in farming operations for handling crops, seeds, and fertilizers.

- Enhance productivity by automating material transport.

- Warehousing and Distribution:

- Streamline logistics by moving goods within warehouses and distribution centers.

- Optimize space and improve order fulfillment processes.

- Food Processing:

- Ensure hygienic and efficient movement of food products through various stages of processing.

- Meet industry regulations and standards for food safety.

- Packaging Industry:

- Assist in the packaging of goods by conveying them to different stages of the packaging process.

- Improve speed and accuracy in packaging operations.

In conclusion, Umar Farooq Belting provides a comprehensive range of conveyor belts to meet the diverse needs of industries. Our commitment to quality ensures that our conveyor belts contribute to increased efficiency, reduced downtime, and improved overall operational performance across various sectors.

Conveyor belts are loops of material that move parts or other items from one location to another. They are often driven by variable speed electric motors or by other moving parts in a complex system. These belts are commonly found in factories, grocery stores, warehouses and public transportation centers.

Before the introduction of modern automation techniques, factory workers often had to travel from project to project. The cumulative effect of all this physical motion was additional stress and inefficient use of the worker’s time. Conveyor belts bring the project to the worker, instead of the worker to the project. Parts could then be transported by other belts to additional workers, and eventually to the shipping docks for delivery.

Further refinement of the conveyor belt allowed factory managers to create automated or semi-automated production lines. Individual parts could be moved through automated machinery for routine processing, leaving workers free for quality control tasks or other higher responsibilities. These devices also proved useful for transporting heavy or hazardous products, reducing worker injuries.

Many conveyor belts work on the principle of variable speed control. If a particular belt moves too slowly, workers may find themselves waiting for parts. If one moves too quickly, parts may be damaged or workers may become overwhelmed. Much of a factory supervisor’s time is spent adjusting the rate at which items move for maximum efficiency. This is especially important in food production factories, where belt speed and proper cooking time work hand in hand.

The use of conveyor belts is not restricted to factories. Bakeries and pizza shops often use a slow-moving wire conveyor belt to move their products through an oven. Grocery stores use them in their check-out lines to bring items to the clerk and bagger. Airports and other public transportation systems use belts to deliver checked baggage to customers, and warehouses use long ones to offload products from incoming trucks or to load outgoing ones. Escalators found in department stores could also be considered conveyor belts, as are “people movers” or moving sidewalks in larger airports.

There many types of Conveyor